Jan. 03, 2022

Jan. 03, 2022

EDM (Electrical Discharge Machining) is capable of machining complex shapes in hard materials and is still the best at the finish.

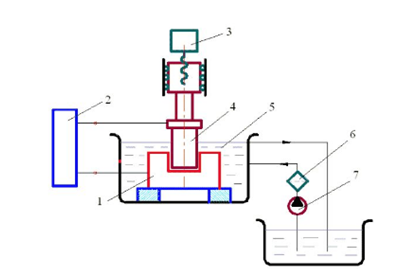

EDM is carried out in a liquid medium, the automatic feeder of the machine tool maintains a proper discharge gap between the workpiece and the tool electrode when a strong pulse voltage is applied between the tool electrode and the workpiece (reaching the breakdown voltage of the dielectric in the gap), the lowest dielectric strength of the dielectric is broken down, as shown in below figure. Because the discharge area is very small and the discharge time is very short, the energy is highly concentrated, so that the temperature of the discharge area is as high as 10000-12000 °C instantaneously, and the metal on the workpiece surface and the tool electrode surface is partially melted or even vaporized. The partially melted and vaporized metal is thrown into the working fluid by the explosive force and cooled to metal particles, which are then quickly washed away from the working area by the working fluid, thus forming a tiny pit on the surface of the workpiece. After a discharge, the dielectric insulation strength of the dielectric is restored and waits for the next discharge. So repeatedly so that the surface of the workpiece is constantly eroded, and copy the shape of the tool electrode on the workpiece, thereby achieving the goal of forming processing.

Electrical discharge machining schematic diagram

1-workpiece, 2-pulse power, 3-automatic feed device, 4-tool electrode, 5-working fluid,6-filter, 7-pump

EDM is the process of removing metal by continuous electrical discharge. Although the duration of a single pulse discharge is short, it is a complex combination of electromagnetism, thermodynamics, and fluid mechanics. Taken together, the process of a pulse discharge can be divided into the following stages,

1, Ionization and breakdown of interelectrode medium and formation of the discharge channel

When the pulse voltage is applied between the tool electrode and the workpiece, an electric field is immediately formed between the two electrodes. The electric field intensity will increase with the increase of the voltage or the decrease of the distance. The dielectric breakdown when the electric field strength increases to a certain amount, the gap current increases rapidly to its maximum value.

2, Dielectric decomposition, melting and vaporization of electrode material

Once the interelectrode medium is ionized and punctured, and a discharge channel is formed, the pulsed power supply makes the electrons between the channels rush to the positive electrode at high speed and the positive ions rush to the negative electrode. Electrical energy becomes kinetic energy, which is converted into heat energy by collision. Therefore, the positive and negative electrode surfaces in the channel become the instantaneous heat source respectively, which reaches a very high temperature. The working liquid is vaporized by channel high temperature, these vaporized liquid and metal vapour become bubbles in the discharge gaps because of the instantaneous volume of a sharp increase, and have rapid thermal expansion and explosive characteristics. Watching the EDM process, you can see bubbles coming out of the discharge gaps, working fluid darkening, and hear a slight, crisp explosion. The EDM is driven by thermal expansion and local microexplosions, which strip away the melted, vaporized electrode material.

3, The throwing of electrode material

The instantaneous high temperature of the channel and the discharge point on the positive and negative electrode surface makes the working liquid vaporize and the metal material melt and vaporize, and the thermal expansion produces very high instantaneous pressure, which causes the vaporized gas to expand outwards, and the molten metal liquid and steam at the top of the channel are squeezed out and thrown out into the working liquid, as a result of the effect of surface tension and cohesion, the material has a minimum surface area, condensation into fine spherical particles.

Molten and vaporized metal is thrown away from the electrode surface, splashing around, except that most of it is thrown into the working fluid and shrunk to small particles, a small portion is splashed, plated, and adsorbed on the opposite electrode surface, which is used to reduce or compensate tool electrode wear during machining under certain conditions.

In fact, the process of metal material erosion and throwing is very complex and people are still finding a deepening understanding of this mechanism.

4, Deionization of interelectrode medium

The pulse current is rapidly reduced to zero with the end of the pulse voltage, but the charged particles are compounded into neutral particles should still be a time interval, restore the dielectric strength of the current discharge channel, and lower the surface temperature of the electrode, in order not to cause the arc discharge in the same place at next time, and to promise the next breakdown discharge channel is formed at the nearest place between the two electrodes or at the lowest resistivity.

Thus, to ensure that the EDM process is carried out properly, there is usually enough time between the two pulse discharges, In addition, there should be room for breakdown, discharge point dispersion and transfer, otherwise, it's easy to form the arc only in the vicinity of the discharge.

Xu Feng provides the EDM service, so feel free to contact us for more interesting information on Electrical Discharge Machining.