Aug. 02, 2023

Aug. 02, 2023

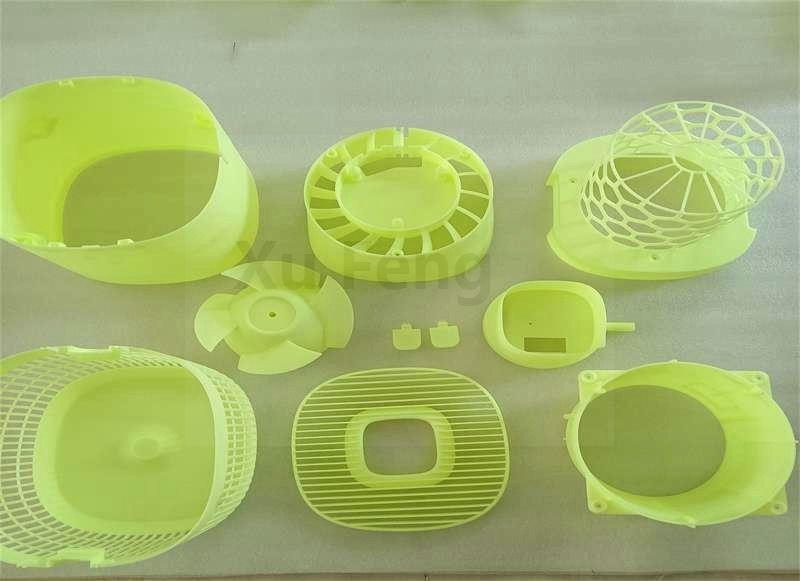

In the realm of product development and innovation, the creation of prototypes is a critical stage that can determine the success of a project. Traditional methods of prototyping can be time-consuming, costly, and limited in design complexity. However, with the advent of 3D printing technology, the landscape of prototyping has been transformed. 3D Printed Prototypes have emerged as a game-changer, enabling faster iteration, cost-effective testing, and unparalleled design possibilities. This article XuFeng explores the features, benefits, and applications of 3D Printed Prototypes, showcasing their role in revolutionizing product development and innovation.

hot tags: CNC Milling Part, CNC Turning Part, CNC Aluminum Part

1. Features of 3D Printed Prototypes

3D Printed Prototypes offer a range of features that set them apart from traditional prototyping methods:

1.1 Speed and Efficiency

One of the most significant advantages of 3D Printed Prototypes is the speed at which they can be produced. Unlike conventional prototyping, which may take days or weeks, 3D printing can create prototypes in a matter of hours, allowing for rapid iteration and design improvements.

1.2 Design Complexity

3D printing technology enables the creation of highly intricate and complex designs that may be impossible or costly to achieve through traditional methods. This opens up new possibilities for innovative and sophisticated product designs.

1.3 Material Versatility

3D printing offers a wide range of materials, from plastics to metals and even composite materials. This versatility allows designers to choose the most suitable material for the specific prototype's intended function and characteristics.

1.4 Cost-Effectiveness

While traditional prototyping methods can be expensive, especially for low-volume production, 3D printing reduces material waste and eliminates the need for costly tooling. This makes 3D Printed Prototypes more cost-effective, particularly for small-batch or customized products.

2. Benefits of 3D Printed Prototypes

The adoption of 3D Printed Prototypes offers several benefits that drive innovation and efficiency in product development:

2.1 Faster Iteration and Refinement

With rapid prototyping capabilities, designers can quickly produce multiple iterations of a product, making it easier to identify design flaws, refine features, and optimize performance.

2.2 Real-World Testing

3D Printed Prototypes allow for functional testing and real-world simulations, enabling designers to validate their concepts and gather valuable feedback before investing in full-scale production.

2.3 Customization and Personalization

3D printing enables the creation of unique and customized products tailored to individual preferences, leading to more personalized and consumer-centric offerings.

2.4 Reduced Time-to-Market

By expediting the prototyping process, 3D printing shortens the time-to-market for new products, allowing companies to stay ahead in competitive markets.

3. Applications of 3D Printed Prototypes

3D Printed Prototypes find applications in a wide range of industries and sectors:

3.1 Aerospace and Automotive

In the aerospace and automotive industries, 3D Printed Prototypes are used to develop lightweight and high-performance components, leading to enhanced fuel efficiency and overall performance.

3.2 Medical and Healthcare

In the medical and healthcare sector, 3D Printed Prototypes enable the creation of patient-specific implants, prosthetics, and medical devices, improving patient outcomes and treatment efficacy.

3.3 Consumer Electronics

In the consumer electronics industry, 3D Printed Prototypes are employed to design and test innovative product designs, such as wearable devices and smart gadgets.

3.4 Architecture and Construction

In architecture and construction, 3D Printed Prototypes assist in creating intricate building components and models, streamlining the design and construction process.

3D Printed Prototypes have revolutionized product development and innovation, offering designers and engineers unparalleled speed, flexibility, and cost-effectiveness. Their ability to create complex designs and test functional prototypes in a short period has paved the way for faster time-to-market and enhanced product performance. From aerospace to healthcare, 3D Printed Prototypes have found applications in various industries, driving the advancement of technology and design. As 3D printing technology continues to evolve, its impact on product development and innovation will undoubtedly expand, ushering in a new era of creativity, customization, and efficiency.