Apr. 24, 2020

Apr. 24, 2020

CNC machining is a high-efficiency, multi-functional automated machine tool.

Bearings are part of CNC machining. Its main function is to support the rotation

of the machine, reduce the friction coefficient generated in its movement, and

ensure its rotation accuracy. So how to disassemble the bearings used in CNC

machining? Let's make CNC Milling Parts Manufacturer think to understand:

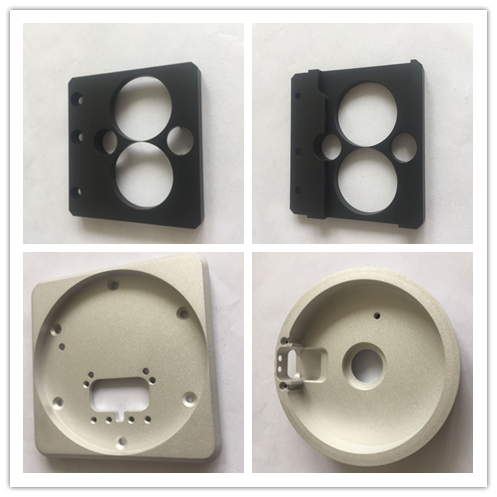

CNC Machined Parts

The bearings used in CNC Machined Parts can be removed by tapping. During tapping, the force is concentrated on the inner ring of the bearing. This method is relatively simple, but it is easy to damage the bearing. When disassembling, place an object pad under the bearing, and then tap lightly with a hammer before removing the bearing. Bearings used in CNC machining can also be pulled out using special pullers during disassembly. The bearing can only be pulled out by turning the handle. It should be noted that the puller should be clamped on the end surface of the inner ring of the bearing, and the bending angle of the puller should be less than 90 °.

The bearings used in CNC machining can also be disassembled by pushing, which can be achieved by a press, and is relatively safe for bearings, but it should be noted that the focus of the press should be placed on the center of the shaft. Bearings used in CNC machining can also be disassembled by hot disassembly. Bearings with approximately 100 degree oil pots can be poured onto the bearings. The principle of thermal expansion and contraction causes the bearing to expand after being heated. At this time, you can pull it out with a pull tool. Use this method slightly to avoid burns. A better method of disassembling the bearing is induction heating, which generates an induction current when the CNC machined the bearing ring, and then the bearing is heated to expand, so that the spindle can be disassembled more conveniently.

CNC machining must comply with the safe operation regulations of the machining center. Before work, wear protective equipment, fasten the cuffs, and don't wear scarves, gloves, ties and apron. Women's braids should be tied in the hat. Before starting the machine, check whether the tool compensation, machine tool zero point and workpiece zero point are normal. is correct. The relative position of each button should meet the operation requirements. Carefully write and input CNC program. Before CNC machining, check the operation of the protection, safety, signal, position, mechanical transmission part, electrical, hydraulic, digital display and other systems on the equipment. Cutting can be done under all normal conditions. Before the trial operation of the machine tool, the operation of the lubrication, mechanical, electrical, hydraulic, digital display and other systems should be checked, and cutting can be performed under all normal conditions.

After the CNC machining machine enters the machining operation according to the program, the operator is not allowed to touch the moving workpiece, tool and transmission part, and it is forbidden to transfer or take tools and other items through the rotating part of the machine.