Oct. 18, 2019

Oct. 18, 2019

Every processing method has its development. If its development is good, it is necessary to look at what kind of product it is. Good product, its development will definitely not be bad. CNC precision parts processing is also the same. The following small series introduces you to the things of CNC precision machining.

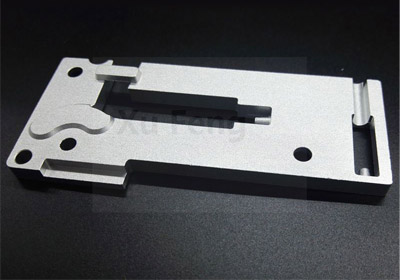

Precision CNC Machined Parts refers to the high precision marked on the production and processing drawings and requires precision machining equipment. The ultra-precision processing equipment of mechanical processing manufacturers mainly include: CNC machining center, precision grinding machine and CNC lathe.

Precision CNC Machined Parts

Correct operation of CNC precision machining:

First, the geometric information and process information on the CNC Machined Parts map are digitized, that is, the relative motion the trajectory of the tool and the workpiece, the change of the spindle speed and the feed speed during the CNC machining, the switch of the coolant, the transformation of the workpiece and the tool, etc. And the operation, the machining program is programmed according to the specified code and format, and then the program is input into the numerical control system.

The numerical control system first performs corresponding calculations and processing according to the requirements of the program, and then issues control commands to coordinate the coordinate axes, the main shafts and the auxiliary actions to realize the relative movement of the tool and the workpiece, and automatically complete the machining of the parts.

The precision of CNC machine tools depends on several factors:

The precision of CNC machine tools and the precision of the machining process are different. They represent two different concepts of CNC machine tools. One is the precision of the machine tool itself and the other is the process of precision it processes. These two reasons seem to be irrelevant, but they are also related.

It is an error to regard the positional accuracy on the CNC Machined Components Manufacturer sample or on the product certificate as the machining accuracy of the machine. The positional accuracy indicated on the sample or certificate is the accuracy of the machine itself, and the machining accuracy is the sum of the errors produced by various factors of the entire process system, including the tolerances allowed by the machine itself. In the selection, the evaluation method of the process capability KP can be referred to as the basis for the accuracy selection.

CNC accuracy has a significant impact on the quality of the process. It is important to note that machining accuracy and machine accuracy are two different concepts. The rigidity of the machine tool directly affects productivity and machining accuracy. The machining speed of the machining center is much higher than that of the ordinary machine tool, and the motor power is also higher than that of the ordinary machine tool of the same specification. Therefore, the rigidity of the structural design is much higher than that of the ordinary machine tool. The order can be checked according to the process requirements, the allowable torque, power, axial force, and maximum feed force according to the values provided by the manufacturer.

CNC precision parts processing can be multi-coordinate linkage, can process parts with complex shapes; high processing precision and stable processing quality; mass production, product quality is easy to control; when machining parts change, generally only need to change the NC program, Save production preparation time; the machine itself has high precision and rigidity, can choose favorable processing amount, high productivity (usually 3~5 times of ordinary machine tools); high degree of machine automation, can reduce labor intensity; professional for operators The quality requirements are lower, and the technical requirements for maintenance personnel are higher.