Finishing Services

We had stable surface treatment partner to cooprate with us to meet various demand surface treatment from our clients.

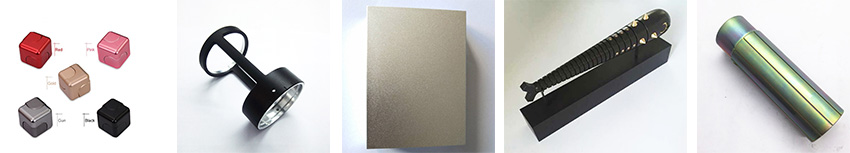

Sandblast/Anodizing Powder coating | Painting | Passivation | electroplate

Sandblast

Propelling very fine bits of material at high-velocity to clean or etch a surface to remove or cover surface contaminants, this usually used before anodizing,painting, passivation to cover the cutter mark.

Anodizing (Anodising)

It is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts.

Anodizing increases resistance to corrosion and wear, and provides better adhesion for paint primers and glues than bare metal does for cnc aluminum parts, anodizing that is most often used surface treatment methold also you can choose the color you want then we can make the anodize color as you want.

Powder coating

It is one kind of painting, the difference with a conventional liquid paint is a powder coating is that the powder coating does not require a solvent to keep the binder and filler parts in a liquid suspension form Powder coating is mainly used for coating of metals, such as automobile parts, electrical parts, household appliances…

Painting

The practice of applying paint, pigment, color or other medium[1] to a solid surface (support base)

That you also can choose the color you want.

Passivation

Passivation involves creation of an outer layer of shield material that is applied as a microcoating, created by chemical reaction with the base material, or allowed to build from spontaneous oxidation in the air

As a technique, passivation is the use of a light coat of a protective material, such as metal oxide, to create a shell against corrosion

Electroplating

Electroplating is a process that uses an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode.

zinc /nickle/chomre elactroplating it is often we used

Tell you demand of surface treatment, we will meet your request.